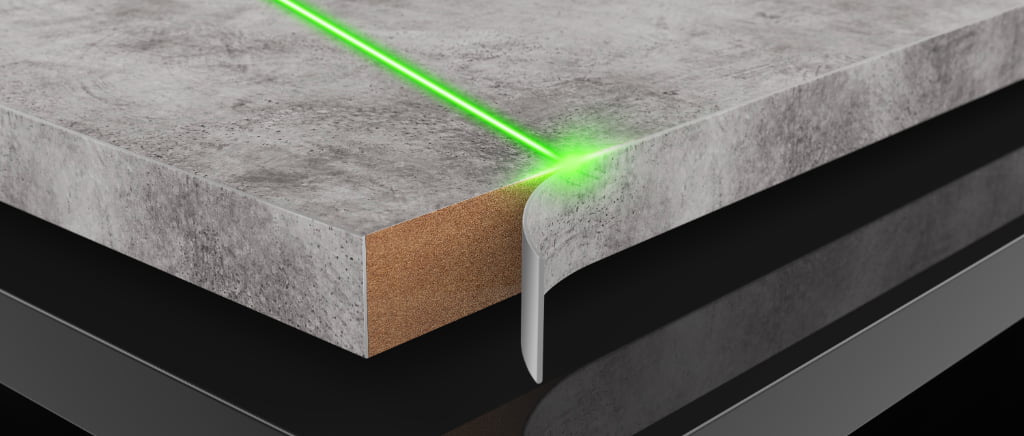

Edge Banding1

Edge Banding2

he real risk is hidden wear layer & foam hardness. Validate by cut-sections + stock proof. We can share 3-batch samples and ready-stock list if you need a clearer comparison.

Technical Highlights

MOQ

300 PC

Size

120*200,200*150

Thickness

2cm

Load container

300 pcs

Need custom specifications? Contact our engineers.

Applications

application 124