Leading Medium Density Board Manufacturers in China

Premium MDF boards with customizable specifications. Established since 1986, serving furniture manufacturers, interior designers, and construction contractors worldwide.

About PGM Woods

Established in 1986, PGM Woods has been a trusted manufacturer of premium medium density boards for over 35 years. Our 100,000㎡ manufacturing facility in Hebei Province, China, houses 12 production lines operated by 100 skilled workers.

We specialize in highly customizable MDF solutions, working with top European suppliers including SESA, HUECK, and FLAI for premium steel plates. Our design team of 10 professionals develops 20-30 new patterns annually to match market trends.

Our MDF Products

High-quality medium density boards for diverse applications

Standard MDF

Premium quality medium density fiberboard with smooth surface finish. Ideal for furniture manufacturing and interior applications.

- Thickness: 15-25mm

- Size: 1220×2440/2745mm

- Grade: E0/E1/ENF

Moisture Resistant MDF

Enhanced moisture resistance for bathroom cabinets and humid environments. Superior performance and durability.

- Water resistant coating

- Bathroom grade quality

- Extended lifespan

Fire Resistant MDF

Specialized fire-retardant medium density board for commercial and institutional projects requiring enhanced safety standards.

- Fire retardant treated

- Commercial grade

- Safety certified

OEM Customization Options

Tailored solutions to meet your specific requirements

Custom Specifications Available

Density Options

Low density (400-600 kg/m³), Medium density (600-800 kg/m³), High density (800+ kg/m³)

Custom Dimensions

Special sizes available with MOQ 2000+ pieces. Standard sizes: 1220×2440mm, 1220×2745mm

Surface Treatments

Melamine facing, UV coating, PET lamination, or raw MDF for your own finishing

Environmental Standards

E0, E1, ENF, F**** grades available with full certification

Cost Analysis & Shipping

Transparent pricing and delivery information

Sample Cost Breakdown

* Prices vary based on specifications, quantity, and market conditions. Contact us for current pricing and detailed quotations.

Shipping Timeline

Requirements Discussion (1-3 days)

Specification confirmation, design matching, and quotation

Production Arrangement (5-10 days)

Material procurement, quality testing, and manufacturing

Quality Control & Packaging (1 day)

Final inspection, testing, and professional packaging

Shipping & Delivery

Container loading and global shipping arrangement

Ready to Start Your MDF Project?

Get a customized quote for your medium density board requirements. Our team will respond within 24 hours with detailed specifications and competitive pricing.

Industry Knowledge & Insights

Expert guidance for your MDF projects

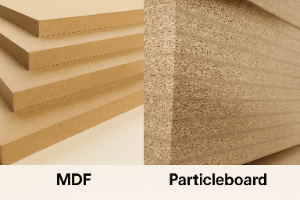

Which is better, particle board or MDF?

Most people feel overwhelmed when choosing between particle board and MDF. They may look the same, but they perform very…

Read More →MDF China: What Global Buyers Should Know Before Importing?

MDF China: What Global Buyers Should Know Before Importing? Every year, more global buyers are turning to China for MDF.…

Read More →How to Choose Reliable MDF Suppliers in China?

Key factors to consider when selecting medium density board manufacturers, including certifications, production capacity, and quality control systems.

Learn the essential criteria →Environmental Standards Impact on MDF Cost

Understanding how E0, E1, and ENF environmental grades affect pricing, applications, and market acceptance of your MDF products.

Explore cost factors →Frequently Asked Questions

Get answers to common MDF manufacturing questions

What is the minimum order quantity for custom MDF specifications?

For standard specifications, our MOQ is one 20ft container (600-700 pieces). For custom sizes and special requirements, the minimum order is typically 2000+ pieces to ensure cost-effective production.

Do you provide MDF samples and what are the costs?

Yes, we provide free samples (4-5 pieces) for evaluation. Shipping costs are determined based on your location. This allows you to test our quality before placing larger orders.

What environmental certifications do your MDF boards have?

Our MDF boards are available in E0, E1, ENF, and F**** environmental grades. We provide full certification documentation and can arrange for additional testing required by your local market.

How do you ensure consistent quality across production batches?

We implement comprehensive quality control throughout the production process, including batch testing for formaldehyde emissions, density standards, moisture content, and surface quality. Each shipment includes detailed quality reports.

Can you match specific colors or provide custom surface treatments?

Yes, we offer extensive customization options. Our design team can match colors from samples you provide or recommend similar alternatives from our extensive catalog of over 200+ patterns and textures.

What are the typical lead times for MDF orders?

Standard specifications: 15-20 days from order confirmation. Custom specifications may require additional 3-5 days for design and setup. We maintain some popular items in stock for faster delivery.

Get Your Custom MDF Quote

Tell us about your requirements and we'll provide detailed specifications and pricing