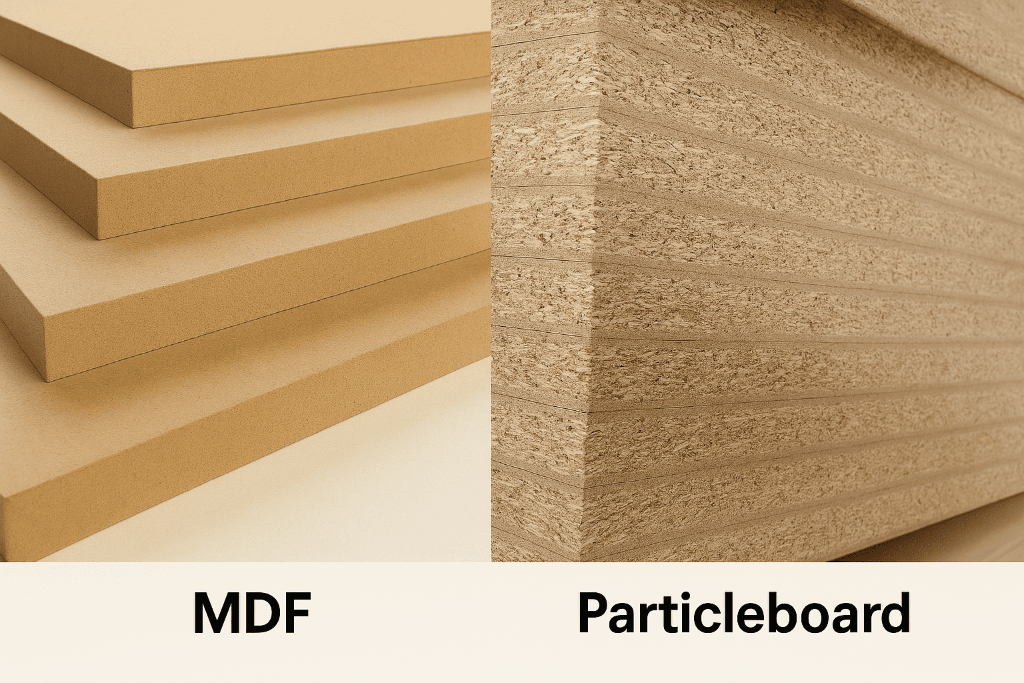

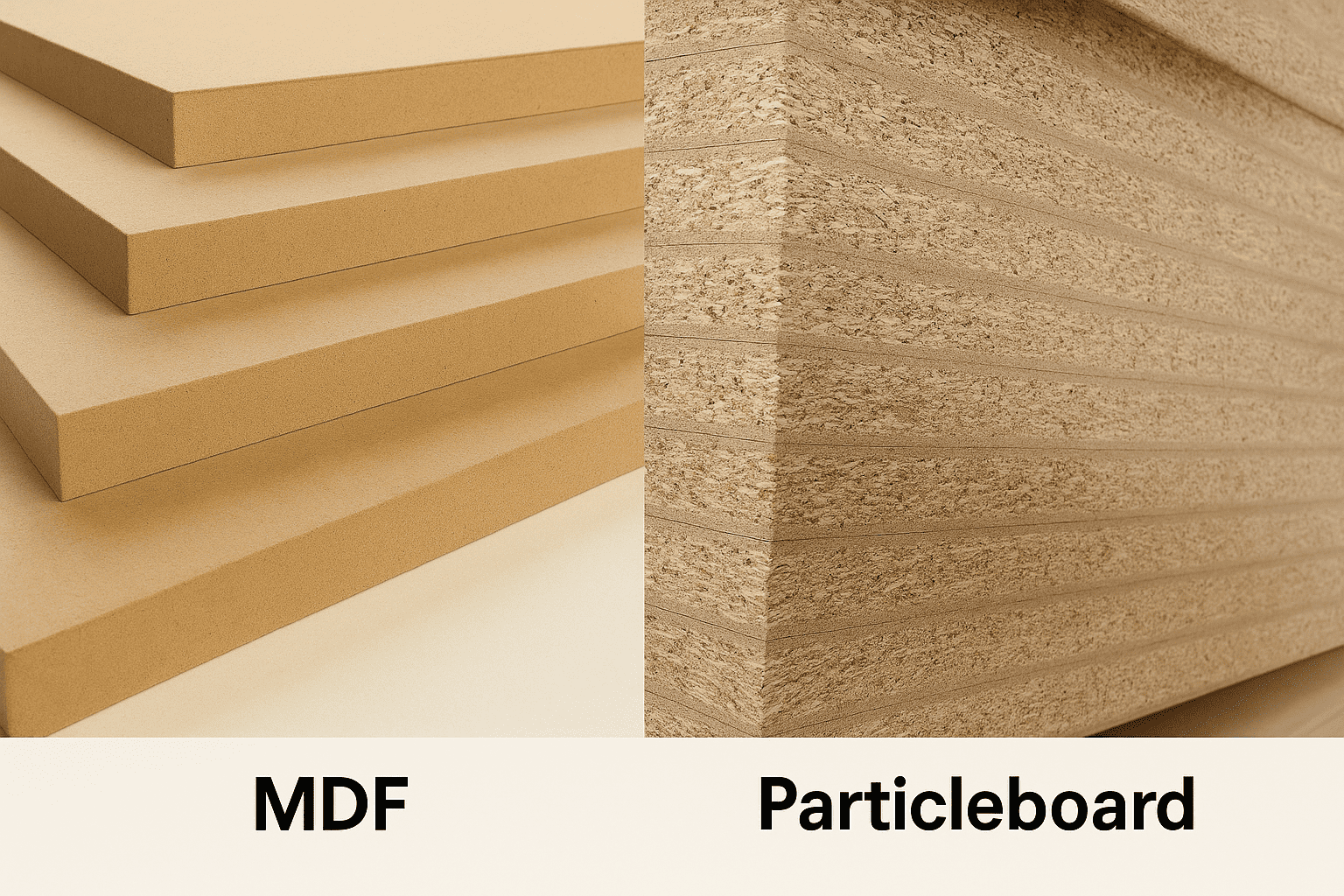

Most people feel overwhelmed when choosing between particle board and MDF. They may look the same, but they perform very differently. Picking the wrong one might cost you time, money, or even your project.

Particle board is better for eco-friendliness, cost-effectiveness, and broader applications. MDF is smoother and stronger but also more expensive and harder to maintain.

Choosing one or the other doesn’t have to be confusing. Let me walk you through the key points so you can decide with confidence.

Which is more expensive, MDF or particle board?

Price often decides everything, especially in large-scale furniture or interior projects. I’ve seen many clients struggle with this.

MDF is generally more expensive than particle board. Particle board sheets cost less and offer more value in budget-focused projects.

Let’s break it down further:

| Material | Average Price Range (USD) | Pros | Cons |

|---|---|---|---|

| Particle Board | $15 – $30/sheet | Affordable, lightweight, versatile | Brittle, weaker in wet areas |

| MDF | $25 – $60/sheet | Smooth, ideal for shaping & painting | Heavier, higher cost |

In my factory, we usually recommend particle board to clients working with limited budgets or large export orders. For clients like Ahmed in Saudi Arabia, who manage big fit-out projects, cutting costs per sheet makes a real difference. For internal millwork that demands clean shapes, though, MDF earns its place despite the higher cost.

What is a particle board called now?

Some customers get confused when they hear different terms. The names vary by region and product specification.

Particle board is also called chipboard. It’s a composite panel made from recycled wood chips and resin, pressed into sheets.

Clarifying the terminology:

In the industry, “chipboard1” and “particle board” usually mean the same thing. Some suppliers also label it as “low-density fiberboard,” but that’s less common. In the Saudi market, I often get asked if "chipboard" is a lower version of MDF—it’s not. It’s just made differently, using larger wood particles and less resin. This is what gives it a lower density and cheaper price.

If you’re buying panels, always check the density rating and the surface finish. At PGM, we provide ENF, E0, or E1-certified boards with melamine finishes. These upgrades make particle board suitable even for visible furniture surfaces, not just internal structures.

Is MDF or particle board better for shelves?

This question comes up a lot, especially for cabinet makers and fit-out contractors. The answer depends on what the shelf is holding.

MDF is better for shelves that carry heavy weight. Particle board is okay for light use or decorative shelving.

Let’s compare:

📦 Load-Bearing

MDF is denser and structurally stronger. It resists bending under heavy weight, which makes it ideal for bookshelves, display racks, or anything holding more than 10kg per shelf. Particle board may start sagging over time if the load is too heavy.

🧰 Custom Fit-Outs

MDF has an edge in precise machining. If you need shelving with curves, edge trims, or seamless finishes, MDF gives cleaner cuts and shapes. Particle board can chip at the edges when milled.

💧 Moisture Zones

Neither material likes moisture, but particle board is especially vulnerable. Without melamine or proper sealing, it will swell. We always recommend using moisture-resistant grades2 or upgrading to plywood in high-humidity areas.

In short, use MDF for high-performance shelving3. Use particle board when cost is more important than strength. Our clients often mix both—particle board in hidden storage, MDF for open shelves.

What’s better than particle board?

Some buyers wonder if there’s a superior alternative to particle board entirely. It depends on what you’re trying to improve.

Plywood is often seen as better than particle board because it’s stronger, more water-resistant, and longer-lasting. But it’s also more expensive.

Comparing your upgrade options:

| Material | Strength | Water Resistance | Price | Ideal Use |

|---|---|---|---|---|

| Particle Board | ★★☆☆☆ | ★☆☆☆☆ | $$ | Cabinets, drawers, low-load use |

| MDF | ★★★☆☆ | ★★☆☆☆ | $$$ | Shelves, paint finishes |

| Plywood | ★★★★☆ | ★★★☆☆ | $$$$ | Flooring, high-load structures |

| OSB | ★★☆☆☆ | ★★☆☆☆ | $$ | Structural panels (not furniture) |

For my clients looking for moisture resistance or outdoor use, I recommend plywood. For general cost-effective indoor furniture, particle board still offers the best balance between price and performance. And for high-end furniture finishes4, MDF wins due to its shaping ability and smooth surfaces.

Conclusion

Both materials serve different needs—choose based on budget, strength, and project type.

-

Get clarity on chipboard terminology and its applications in furniture making. ↩

-

Learn about moisture-resistant options to enhance the durability of your furniture. ↩

-

Discover the best materials for shelving that can withstand heavy loads and moisture. ↩

-

Learn about materials that provide superior finishes for high-end furniture projects. ↩